Products & Systems T1 Steel

High-quality type 1 steel cylinders from heiserTEC for demanding applications in industry, medicine, and research.

The heiserTEC T1 steel cylinder is the perfect solution for the safe and reliable storage and transport of high-pressure gases. With the lowest weight class on the market, optimized geometry, and an ultra-clean interior, the T1 steel cylinder offers performance and efficiency for a wide range of industrial applications.

The T1 steel cylinder is ideal for storing industrial gases, alternative fuels such as hydrogen (H2) and natural gas (CNG), as well as other high-pressure gases. Its robust construction and precise manufacturing make it particularly durable and safe, even under the toughest conditions.

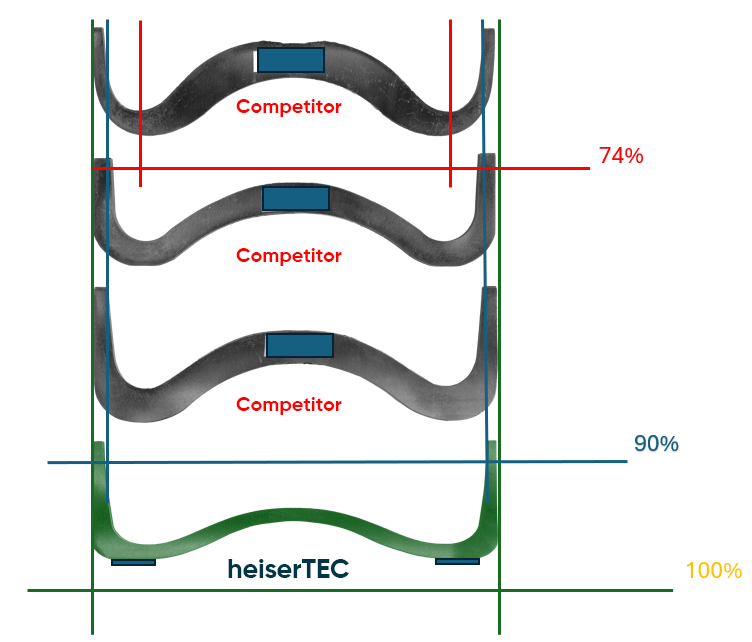

Compared to competitors in Europe and Asia, our Type 1 steel cylinders are 10-30 % lighter

Why choose the heiserTEC Type 1 steel cylinder?

The T1 steel cylinder from heiserTEC is the perfect choice for companies that need a reliable, lightweight, and safe solution for gas storage and transport. The combination of low weight, optimized shape, and high safety standards makes the T1 steel cylinder the preferred choice in the industry.

The heiserTEC Type 1 steel cylinder has been developed for a wide range of applications that require reliable and safe storage of high-pressure gases.

The heiserTEC Type 1 steel cylinder has been developed for a wide range of applications that require reliable and safe storage of high-pressure gases.

The T1 steel cylinder is ideal for storing and transporting compressed hydrogen (H2) and natural gas (CNG), especially for applications in transportation and energy supply.

The T1 steel cylinder is used in research environments where precision and reliability are essential. It ensures a constant gas supply, thereby guaranteeing stable scientific experiments.

Our T1 steel cylinders are available in various sizes and pressure ratings to meet different requirements. The technical specifications ensure high flexibility and perfect adaptation to the needs of your industry.

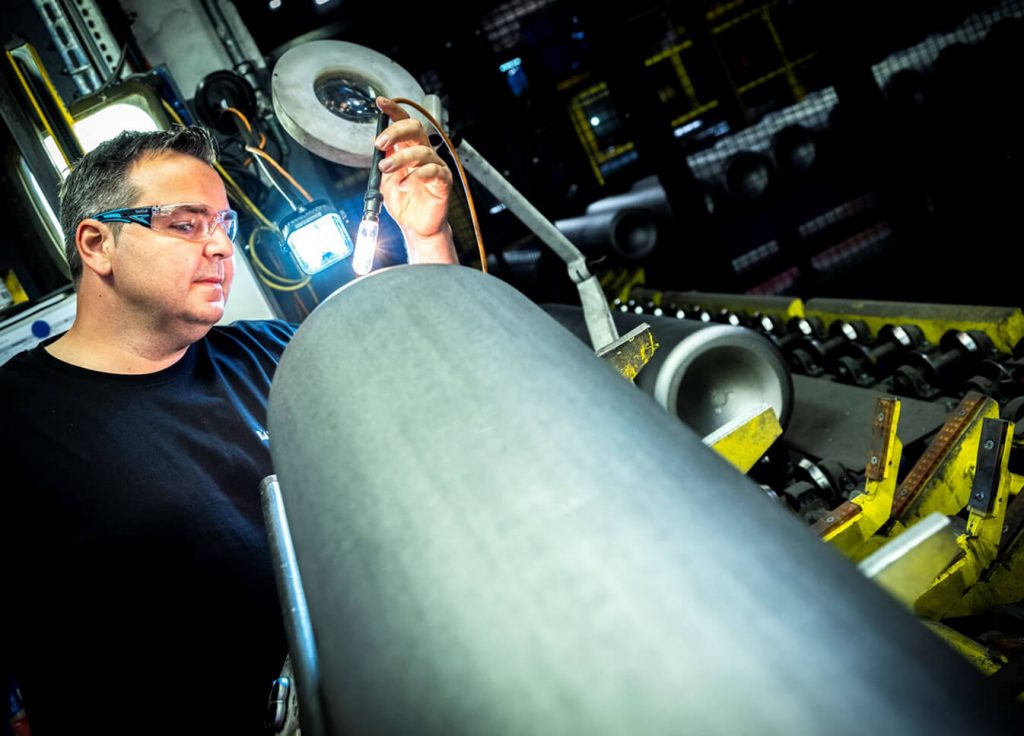

Safety is the foundation of our production. Manufactured to the highest quality standards, the heiserTEC Type 1 steel cylinder ensures:

The T1 steel cylinder is available in various designs to meet the requirements of your industry. Whether you need smaller cylinders for precision work or larger ones for industrial applications, we have the right option for you.

Contact us today to configure your heiserTEC Type 1 steel cylinder!

Water Capacity (L) | Range (L)* | Regulativ | Working Pressure (BAR) | Test Pressure (BAR) | Diameter (MM) | Length (MM) | Weight (KG)** | Base | Neck Ring | |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 - 1,6 | TPED | (EN) ISO 9809-1 | 200 | 300 | 83 | 280 | 2,1 | concave | without |

| 2 | 1,5-3,2 | TPED | (EN) ISO 9809-1 | 200 | 300 | 100 | 345 | 3,4 | concave | with |

| 10 | 3-13,5 | TPED | (EN) ISO 9809-1 | 200 | 300 | 140 | 820 | 12,8 | concave | with |

| 10 | 6-13 | TPED | (EN) ISO 9809-1 | 300 | 450 | 178 | 585 | 21 | concave | with |

| 20 | 12,5-43 | TPED | (EN) ISO 9809-1 | 200 | 300 | 204 | 820 | 27,5 | concave | with |

| 20 | 12-30 | TPED | (EN) ISO 9809-1 | 300 | 450 | 204 | 860 | 41 | concave | with |

| 50 | 17-64 | TPED | (EN) ISO 9809-1 | 200 | 300 | 229 | 1465 | 54 | concave | with |

| 50 | 15-60 | TPED | (EN) ISO 9809-1 | 300 | 450 | 229 | 1560 | 81,5 | concave | with |

| 50 | 15-58 | TPED | (EN) ISO 9809-1 | 330 | 495 | 229 | 1600 | 94 | concave | with |

| 50 | 15-60 | PED | EN1964-1 | 330 | 472 | 229 | 1565 | 85,5 | concave | with |

| 50 | 15-60 | PED | (EN) ISO 9809-1 | 330 | 495 | 229 | 1600 | 97 | concave | with |

| 50 | 15-60 | PED | EN1964-1 | 330 | 495 | 229 | 1600 | 94 | concave | with |

| 50 | 15-55 | PED | (EN) ISO 9809-1 | 400 | 572 | 229 | 1670 | 113 | convex | without |

| 50 | 13,5-55 | TPED | (EN) ISO 9809-1 | 400 | 600 | 229 | 1680 | 119 | concave | with |

| 50 | 12-50 | PED | (EN) ISO 9809-1 | 550 | 787 | 229 | 1850 | 175 | convex | without |

| 50 | TPED | (EN) ISO 9809-1 | 500 | 750 | 229 | 1800 | 150 | convex | with | |

| 50 | TPED | (EN) ISO 9809-1 | 500 | 750 | 267 | 1350 | 152 | convex | with | |

50 | TPED | (EN) ISO 9809-1 | 500 | 750 | 229 | 1790 | 154 | concave | with | |

| 50 | 18-50 | TPED | (EN) ISO 9809-1 | 550 | 825 | 267 | 1400 | 175 | convex | without |

| 50 | 18-50 | PED | (EN) ISO 9809-1 | 550 | 787 | 267 | 1400 | 175 | convex | without |

* Any size in-between can be offered upon request.

** If the bottle has a neck ring, it is included in the weight.

| Acetylene Capacity (KG) | Water Capacity (L) | Range (L)* | Regulativ | Working Pressure (BAR) | Test Pressure (BAR) | Diameter (MM) | Length (MM) | Weight (KG) | Base | |

|---|---|---|---|---|---|---|---|---|---|---|

| 0,9 | 5 | 3-13,6 | TPED | (EN) ISO 9809-1 | 18 | 60 | 140 | 440 | 6,3 | concave |

| 1,8 | 10 | 3-13,6 | TPED | (EN) ISO 9809-1 | 18 | 60 | 140 | 800 | 10,2 | concave |

| 1,8 | 10 | 8-16 | TPED | (EN) ISO 9809-3 | 18 | 60 | 171 | 575 | 10,5 | concave |

| 1,8 | 10 | 6-16 | TPED | (EN) ISO 9809-3 | 18 | 60 | 178 | 535 | 10,2 | concave |

| 4 | 20 | 13,4-40 | TPED | (EN) ISO 9809-3 | 19 | 60 | 204 | 780 | 19,5 | concave |

| 8 | 40 | 20-45 | TPED | (EN) ISO 9809-3 | 19 | 60 | 204 | 1430 | 31 | concave |

| 8 | 40 | 20-60 | TPED | (EN) ISO 9809-3 | 16 | 60 | 229 | 1150 | 29 | concave |

| 10 | 50 | 20-50 | TPED | (EN) ISO 9809-3 | 19 | 60 | 229 | 1400 | 34,5 | concave |

| 17,98 | 58 | 25-60 | TPED | (EN) ISO 9809-3 | 19 | 60 | 267 | 1240 | 44,5 | concave |

Every bottle includes a neck ring.

* Any size in-between can be offered upon request

| Water Capacity (L) | Range (L)* | Regulativ | Working Pressure (BAR) | Test Pressure (BAR) | Diameter (MM) | Length (MM) | Weight (KG) | Base Shape | Neck Ring | |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 - 1,6 | TPED | (EN) ISO 9809-1 | 200 | 300 | 83 | 260 | 1,5 | convex | without |

| 2 | 1,5-7 | TPED | (EN) ISO 9809-1 | 200 | 300 | 100 | 345 | 3,4 | concave | with |

| 3 | 1,5-7 | TPED | (EN) ISO 9809-1 | 200 | 300 | 100 | 490 | 4,5 | concave | with |

| 5 | 3-13,5 | TPED | (EN) ISO 9809-2 | 200 | 300 | 140 | 440 | 6,4 | concave | with |

| 5 | 3-13,6 | TPED | (EN) ISO 9809-2 | 200 | 300 | 140 | 435 | 5,6 | concave | with |

| 10 | 3-13,5 | TPED | (EN) ISO 9809-2 | 200 | 300 | 140 | 800 | 10,2 | concave | with |

| 10 | 3-13,6 | TPED | (EN) ISO 9809-2 | 200 | 300 | 140 | 795 | 8,9 | concave | with |

| 10 | 6-16 | TPED | (EN) ISO 9809-1 | 200 | 300 | 178 | 545 | 12,6 | concave | with |

| 10 | 6-16 | TPED | (EN) ISO 9809-2 | 300 | 450 | 178 | 555 | 15,7 | concave | with |

| 13,4 | 13,4-45 | TPED | (EN) ISO 9809-2 | 166 | 250 | 204 | 560 | 16,5 | concave | with |

| 13,4 | 13,4-45 | TPED | (EN) ISO 9809-2 | 200 | 300 | 204 | 565 | 16,5 | concave | with |

| 14 | 6-21 | TPED | (EN) ISO 9809-2 | 200 | 300 | 178 | 715 | 14,5 | concave | with |

| 20 | 12,5-30 | TPED | (EN) ISO 9809-2 | 300 | 450 | 204 | 820 | 30,5 | concave | with |

| 20 | 13,4-45 | TPED | (EN) ISO 9809-2 | 200 | 300 | 204 | 780 | 21 | concave | with |

| 26,8 | 12-50 | TPED | (EN) ISO 9809-2 | 166 | 250 | 204 | 1000 | 24,5 | concave | with |

| 30 | 13,4-45 | TPED | (EN) ISO 9809-2 | 166 | 250 | 204 | 1105 | 27 | concave | with |

| 30 | 16-62 | TPED | (EN) ISO 9809-2 | 300 | 450 | 228,4 | 945 | 41,5 | concave | with |

| 30 | 17-70 | TPED | (EN) ISO 9809-2 | 200 | 300 | 229 | 890 | 29 | concave | with |

| 40 | 11-50 | TPED | EN1964-2 | 300 | 450 | 204 | 1510 | 51 | concave | with |

| 40 | 12-50 | TPED | (EN) ISO 9809-2 | 200 | 300 | 204 | 1440 | 35 | concave | with |

| 40 | 16-62 | TPED | (EN) ISO 9809-2 | 300 | 450 | 228,4 | 1215 | 51,5 | concave | with |

| 40 | 17-70 | TPED | (EN) ISO 9809-2 | 200 | 300 | 229 | 1145 | 35 | concave | with |

| 50 | 15-55 | TPED | (EN) ISO 9809-2 | 400 | 600 | 229 | 1565 | 85,5 | concave | with |

| 50 | 16-60 | TPED | (EN) ISO 9809-2 | 350 | 525 | 229 | 1540 | 75 | concave | with |

| 50 | 16-62 | TPED | (EN) ISO 9809-2 | 300 | 450 | 228,4 | 1485 | 61 | concave | with |

| 50 | 17,5-66 | TPED | (EN) ISO 9809-2 | 166 | 250 | 229 | 1415 | 40,5 | concave | with |

| 50 | 17,5-66 | TPED | (EN) ISO 9809-2 | 200 | 300 | 229 | 1405 | 41 | concave | with |

| 50 | 17-65 | TPED | (EN) ISO 9809-1 | 200 | 300 | 229 | 1445 | 48,5 | concave | with |

| 50 | 18-55 | TPED | (EN) ISO 9809-2 | 414 | 621 | 228,4 | 1575 | 89 | concave | with |

| 67,5 | 25-90 | TPED | (EN) ISO 9809-2 | 200 | 300 | 267 | 1430 | 59,5 | concave | with |

| 67,5 | 25-91 | TPED | (EN) ISO 9809-2 | 166 | 250 | 267 | 1410 | 54 | concave | with |

| 80 | 25-85 | TPED | (EN) ISO 9809-2 | 300 | 450 | 267 | 1750 | 98 | concave | with |

| 80 | 25-90 | TPED | (EN) ISO 9809-2 | 200 | 300 | 267 | 1670 | 68 | concave | with |

* Any size in-between can be offered upon request

Subject to change

The heiserTEC Type 1 steel cylinder is suitable for storing a wide range of industrial gases, such as oxygen, nitrogen, argon, as well as alternative fuels such as hydrogen (H2) and natural gas (CNG).

Yes, our high-pressure cylinders can withstand working pressures of up to 550 bar (tested at 825 bar test pressure) and are therefore also ideal for high-pressure hydrogen gas. You can find various solutions for storing and transporting hydrogen here.

The heiserTEC Type 1 steel cylinder meets the highest quality standards and has been tested for a wide range of certifications, such as ISO 9809-1, EN 1964, and UN/DOT standards. If you have any questions about specific certifications, please do not hesitate to contact us!

Then contact us for detailed product specifications, prices, and availability.

Click below for detailed product specifications, pricing, and availability.